Product Introduction

Texture paint, with its infinitely variable three-dimensional texture and multiple personalized matching options, presents a unique spatial perspective, rich and vivid, refreshing and innovative. A new type of artistic coating, bringing the smooth era of wall coatings into a new era of natural and environmentally friendly textured coatings.

Application Areas

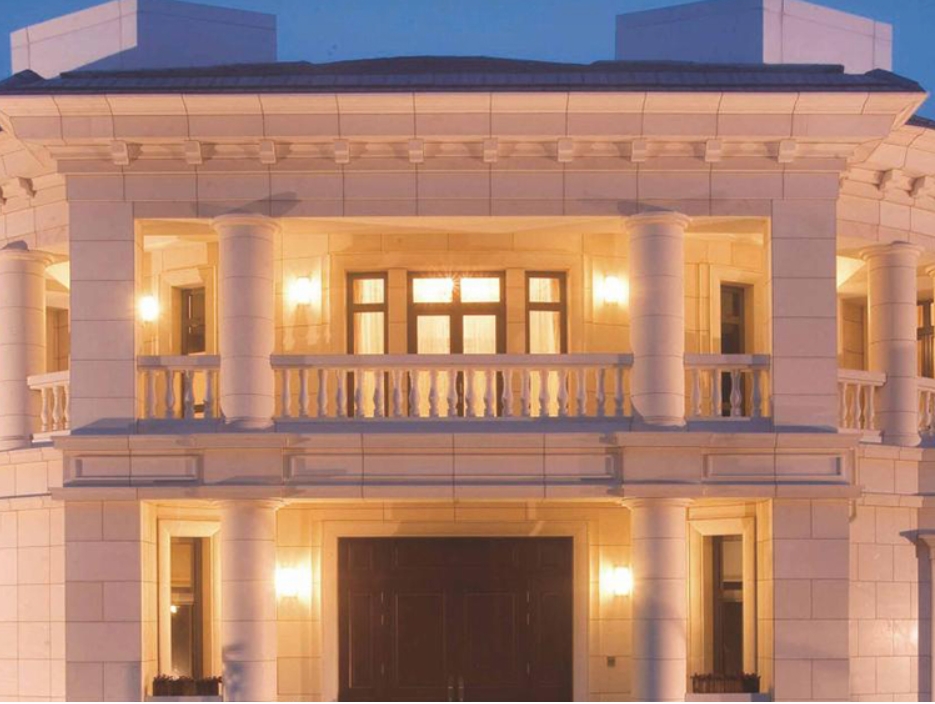

Textured coatings have a wide range of applications. Generally, textured coatings are commonly used in villas, offices, hotels, guesthouses, or high-end residential areas, and are also widely used in indoor pastoral-style decoration design.

Film Properties

| Serial Number | Test Item | Standard Requirements | Test Results | Single Item Conclusion |

| 1 | Appearance of the Film | Coating appearance normal | Conforms | Qualified |

| 2 | Surface Drying Time, h | ≤2 | 2 | Qualified |

| 3 | Through Drying Time, h | ≤24 | 24 | Qualified |

| 4 | Adhesion | ≥1 | 1 | Qualified |

| 5 | Complete Curing, d | ≥7 | 7 | Qualified |

Main Characteristics

1. Natural and environmentally friendly, non-toxic and odorless, waterproof and with good breathability;

2. Strong decorative texture, freely created three-dimensional patterns, and excellent aging resistance;

3. Alkali-resistant and anti-corrosion, water-washable, no peeling, no cracking, no fading; its excellent quality ensures use for more than ten years;

4. Anti-toxic and mildew-proof, preventing the growth of wall mold, safe and hygienic.

Construction Method

1. The base surface must be clean, dry, completely cured, free of oil stains, dust, mildew spots, loose material, peeling, blistering, and powdering; 2. Stir thoroughly before construction. Apply one coat with an ordinary putty knife. It must be fully dried for more than 24 hours before proceeding to the next step. Sanding must be even.

3. For textured effects, texture processing should be done 5 minutes after the main material is smoothed. Usually, two people work as a team; one person applies and smooths the material, and the other person creates the texture.

processing.

4. After complete drying, sand smooth.

5. When applying the final topcoat, ensure that one work area is coated at a time to avoid leaving coating joints.

6. If the finished decorative surface needs repair, the entire work area should be recoated. Avoid partial recoating to prevent obvious recoating marks.

7. Avoid coating when the base surface temperature is extremely high (such as prolonged sun exposure in summer). If coating is necessary, take appropriate cooling measures first, such as spraying cold water, and allow the base surface to dry before coating.

8. The relative humidity of the coating environment should be below 85%, and the base surface moisture content should be below 10% and the PH value below 10 before coating.

Packaging and Storage

Package and store according to national regulations. The storage environment should be dry, cool, and well-ventilated, avoiding high temperatures and keeping away from fire sources. The packaging container must remain sealed. The effective storage period is 6 months.

Precautions

Outdoor construction is not suitable if the base material temperature is below 5°C.

Health and Safety

Note the warning labels on the packaging container. Use in a well-ventilated area. Do not inhale paint mist and avoid skin contact. If paint splashes on the skin, immediately wash with a suitable cleaning agent, soap, and water. If paint splashes in the eyes, rinse thoroughly with water and seek immediate medical attention.

Declaration

The information provided in this product specification is entirely based on our understanding gained from laboratory and practical experience. However, since product use is generally beyond our control, we only guarantee the quality of the product itself. We reserve the right to modify this specification without prior notice.

Sample Display

Related Products

Product Inquiry