Product Introduction

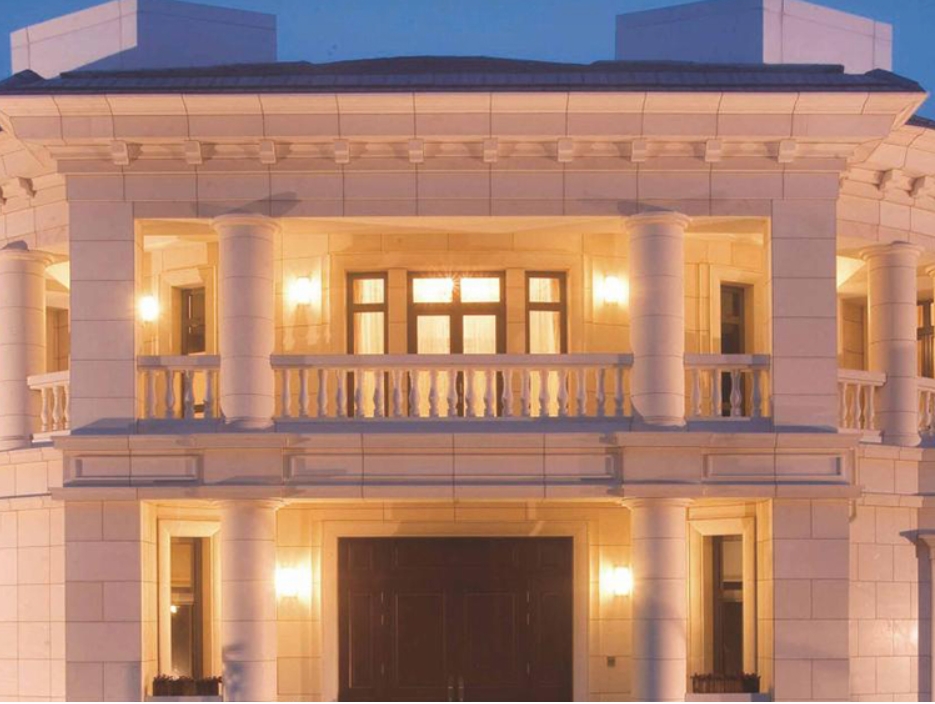

Water-wrapped sand coating combines the realism of water-wrapped water coating with the texture of real stone paint. This product is widely used in various high-end projects, greatly improving the quality of the project. The decorative effect of water-wrapped sand coating is comparable to that of real stone.

Application Areas

Mountain villas, hotels, guesthouses, entertainment venues, commercial clubs, cement fiber boards, plaster surfaces, gypsum moldings, various partition boards, ceilings, and other large-area interior and exterior walls of buildings.

Film Properties

| Serial Number | Test Item | Standard Requirements | Test Results | Single Item Conclusion |

| 1 | Appearance of the paint film | Normal coating appearance | Conforms | Qualified |

| 2 | Surface drying time, h | ≤2 | 2 | Qualified |

| 3 | Through-drying time, h | ≤24 | 24 | Qualified |

| 4 | Adhesion | ≥1 | 1 | Qualified |

| 5 | Complete curing, d | ≥7 | 7 | Qualified |

Main Characteristics

A single spray application can produce a variety of colorful, randomly sized lychee-textured marble effects. This product is easy to apply, highly realistic, and costs only 30% of marble. It has good flexibility, strong crack-covering ability, and a matching primer, with excellent bonding strength, water and alkali resistance, stain resistance, and weather resistance.

Construction Method

Pre-coating treatment of various substrates to meet the corresponding coating conditions:

1. Concrete, cement putty, external insulation rendering mortar surface: The surface must be clean. The PH value should be maintained below 10, and the water content should be below 85%. Steel bars and iron sheets must be treated with anti-rust paint first.

2. Cement pressure plates, calcium silicate boards, fireproof boards, GRC boards, ALC boards - If the substrate is uneven, it must be repaired with crack-resistant putty.

3. Wood: Wood treatment generally starts with an oil-based primer, followed by a water-based coating to seal oil-soluble substances. Composite board treatment generally starts by filling the joints with elastic sealant, then bonding with gauze.

4. General walls should be applied with 2-3 coats of exterior flexible putty.

Packaging and Storage

Packaging and storage according to national regulations. The storage environment should be dry, cool, and well-ventilated, avoiding high temperatures and keeping away from fire sources. The packaging containers must be kept sealed.

The effective storage period is 6 months.

Precautions

Outdoor construction should not be carried out when the substrate temperature is below 5°C.

Health and Safety

Please pay attention to the warning signs on the packaging container. Use in a well-ventilated environment. Do not inhale paint mist, avoid skin contact. If paint splashes on the skin, immediately wash with a suitable cleaning agent, soap, and water. If it gets into the eyes, rinse thoroughly with water and seek immediate medical attention.

Declaration

The information provided in this product specification is entirely based on our understanding gained from laboratory and practical experience. However, since the use of the product is usually beyond our control, we only guarantee the quality of the product itself. We reserve the right to modify this specification without prior notice.

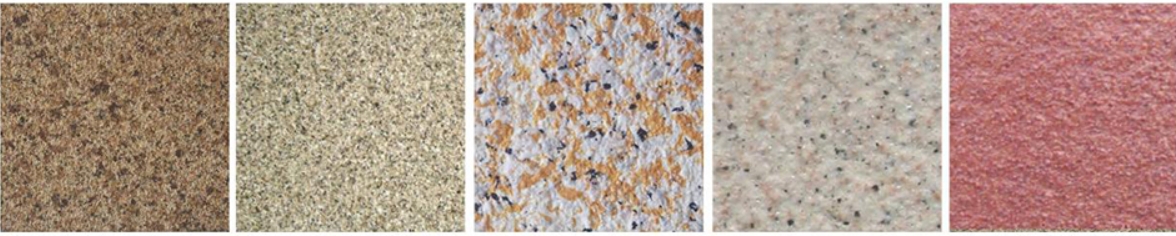

Sample Display

Water-based sand paint

Contact Us

Belonging Category

Related Products

Product Inquiry